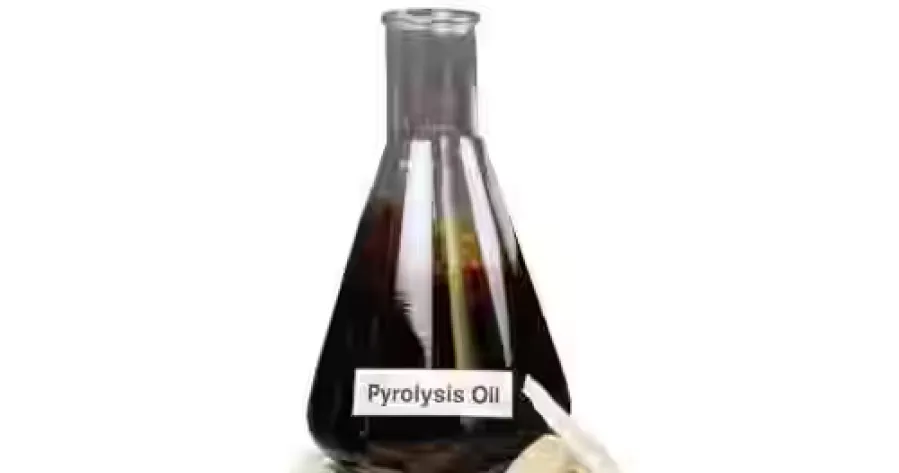

Turning Waste into Sustainable Energy through Pyrolysis Oil

Pyrolysis oil is the end product of waste rubber tire and plastic pyrolysis. It is widely used as an industrial fuel replacement for industrial renewable fuel oil . Ordinary industrial uses for pyrolysis oil as fuel don't call for premium fuel because it's mainly used in machines.

How Do We Use Pyrolysis Oil?

Pyrolysis oil, a valuable byproduct of crumb tire recycling, is produced by heating shredded tires without oxygen, breaking them down into oil, gas, and carbon black. Here’s how pyrolysis oil is commonly used:

Pyrolysis oil offers a sustainable, lower-cost alternative to traditional fossil fuels in industrial applications, reducing reliance on crude oil and providing a sustainable fuel source.

Pyrolysis oil, rich in hydrocarbons, can be refined to extract valuable chemicals like benzene, toluene, and xylene, essential for petrochemical industry products like plastics, rubber, and synthetic fibers.

Use Of Pyrolysis oil

Fuel Substitute

Pyrolysis oil serves as an alternative fuel in industrial applications like cement and steel plants, reducing reliance on fossil fuels and lowering energy costs.

Blending Component For Renewable Fuel Oil

Pyrolysis oil can be blended with renewable fuel oil after refining, providing a partially renewable fuel source that reduces emissions and promotes a more sustainable fuel consumption approach.

Chemical Production

Pyrolysis oil, rich in valuable chemicals like carbon black and sulfur, can be utilized in various chemical and industrial processes, including rubber and plastic manufacturing.

Energy Source For Pyrolysis Plants

Recycling plants use pyrolysis oil as a heat source to power the reactor, enhancing energy efficiency and reducing external fuel requirements.

Hydrocarbon Feedstock

Pyrolysis oil serves as a crucial hydrocarbon feedstock for refining into gasoline, renewable fuel oil , and other petrochemicals, making it a vital resource for various industrial applications requiring hydrocarbon-based inputs.

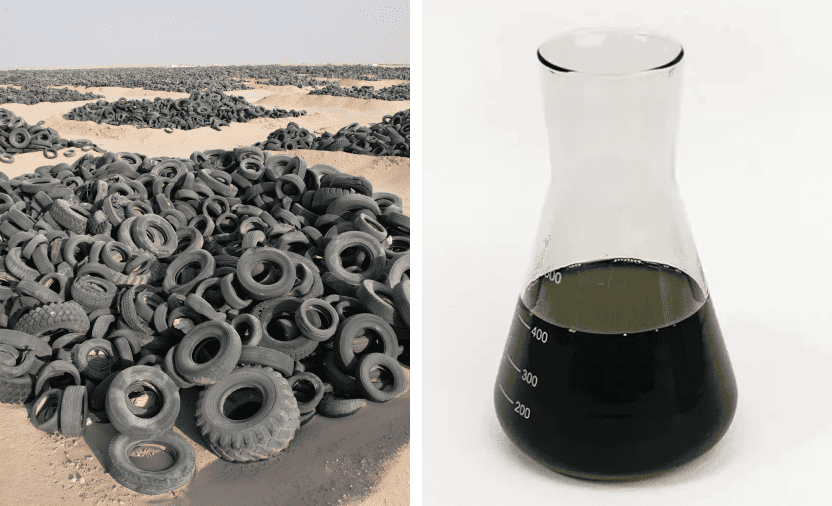

Reducing Waste, Reclaiming Resources

We help you lead the way in tire recycling

At EPS we're committed to minimizing waste and maximizing resource utilization. Our innovative recycling processes transform discarded tires into valuable products, such as rubber mulch, crumb rubber, and recycled carbon black. By reclaiming these resources, we reduce landfill waste and promote a more sustainable future. Join us in creating a circular economy where waste is minimized and resources are conserved.

Pyrolysis Oil Production at EPS

Pyrolysis oil, a key product of tire recycling, is produced by heating scrap tires in an oxygen-free environment, transforming them into valuable energy-rich products. EPS uses advanced technologies to transform scrap tires into valuable pyrolysis oil, promoting sustainable energy solutions and resource conservation, thereby reducing waste and reclaiming resources.

Interested in our products?

Ready to explore the possibilities of tire recycling? Contact us today to learn more about our products and customized solutions. Our team of experts is eager to assist you in achieving your sustainability goals.

Our Certificates

Our Own Recycling Facilities

Organization:

EPS Group

Phone Number:

Email Address:

Website:

www.epstyrerecycling.com

Office Hours:

Monday To Saturday 9:00 AM to 6:00 PM

Office 1

Organization:

Hunan Benji

Environmental Energy Technology Co., LTD

Environmental Energy Technology Co., LTD

Phone Number:

Email

Address:

Address:

Office Hours:

Monday To Saturday 9:00

AM to 6:00 PM

AM to 6:00 PM

Get In Touch

Our team is available to assist with questions, inquiries, and tire range information, as well as advice on vehicle options and services.