Manual/Semi-Automatic Machinery -Efficient Solutions For Sustainable Rubber Recycling

Manual/Semi-Automatic Crumb Rubber Machinery Recycles And Processes Waste Rubber, Like Used Tires, Into Crumb Rubber, A Valuable Raw Material Used In Various Industries For Various Applications.

Rubber Recycling Reduces Landfill Waste By Breaking Down Waste Rubber Into Smaller Crumbs. Crumb Rubber Is Produced For Various Industries, Including Construction, Sports, And Automotive. It Is Used In Rubberized Asphalt For Improved Road Durability And Noise Reduction. Rubber Granules Are Used In Playground Surfaces, Sports Fields, Gym Mats, And Flooring. Rubber Crumbs Are Also Used In Landscaping And Erosion Control. Rubber-based products, Such As Shoe Soles And Carpet Padding, Are Produced, Extending The Lifespan Of Rubber. Overall, Recycling Contributes To The Eco-Friendly Disposal Of Rubber Products.

Therefore, Manual/Semi-Automatic Crumb Rubber Machinery Is Essential To The Environmentally Friendly Cycle Of Recycling Rubber, Turning Waste Rubber Into Useful Products For A Variety Of Sectors.

Manual/Semi-Automatic Machinery -Efficient Solutions For Sustainable Rubber Recycling

Manual/Semi-Automatic Crumb Rubber Machinery Recycles And Processes Waste Rubber, Like Used Tires, Into Crumb Rubber, A Valuable Raw Material Used In Various Industries For Various Applications.

Rubber Recycling Reduces Landfill Waste By Breaking Down Waste Rubber Into Smaller Crumbs. Crumb Rubber Is Produced For Various Industries, Including Construction, Sports, And Automotive. It Is Used In Rubberized Asphalt For Improved Road Durability And Noise Reduction. Rubber Granules Are Used In Playground Surfaces, Sports Fields, Gym Mats, And Flooring. Rubber Crumbs Are Also Used In Landscaping And Erosion Control. Rubber-based products, Such As Shoe Soles And Carpet Padding, Are Produced, Extending The Lifespan Of Rubber. Overall, Recycling Contributes To The Eco-Friendly Disposal Of Rubber Products.

Therefore, Manual/Semi-Automatic Crumb Rubber Machinery Is Essential To The Environmentally Friendly Cycle Of Recycling Rubber, Turning Waste Rubber Into Useful Products For A Variety Of Sectors.

Advantage Of Manual/Semi-Automatic Machinery

High Value Of The Byproduct

Energy Generation

Landscaping And Erosion Control

Sustainable Waste Handling

Resource Recovery

We provide plants that comply with Indian environmental standards and government SOP regulations.

Tyre sidewall cutter

Specification :

A tire sidewall cutter in recycling machinery, particularly for producing crumb rubber, uses mechanical shearing and cutting, rotary motion, force amplification, and material handling and positioning. It uses hardened steel blades or rotary cutters to shear through rubber and steel belts, ensuring precise separation. The machine rotates the tire around a central axis, ensuring an even cut around the tire circumference. Proper positioning reduces vibration, producing cleaner cuts for subsequent processes.

| Model | Motor (kw) | Processing range (mm) | Weight (kg) | Dimension (mm) | Production |

| EPS310 | 9.5 | 750-1200 | 580 | 1440*1000*1540 | 60-80 pieces tire/hour |

|---|

Automatic tire strips cutter

Specification :

An automatic tire strips cutter in tire recycling machinery for crumb rubber production uses mechanical and automation principles. It uses high-tensile steel blades to shear tires into strips, with some machines employing rotary cutting or reciprocating motion. Automation and precision control are ensured through sensors and programmable logic controllers. Hydraulic or pneumatic systems provide force for cutting, enhancing efficiency. Tires are either manually loaded or automatically fed into the machine, ensuring continuous operation and high throughput.

| Model | Motor (kw) | Processing range (mm) | Diameter of round blades(mm) | Weight (kg) | Dimension (mm) | Production |

| EPS380 | 8.5 | 750-1200 | 380 | / | 1800*900*1580 | 15-20 |

|---|---|---|---|---|---|---|

| EPS600 | 10.5 | 750-1200 | 600 | 1400 | 2190*950*1780 | 30-40 |

Tire blocks cutter

Specification:

A tire blocks cutter is a machine used in tire recycling machinery to produce crumb rubber. It uses mechanical shearing and block cutting, force amplification through leverage or hydraulics, reciprocating motion or rotary blades, material positioning and feeding, and automation control in semi-automatic models. These principles ensure precise block separation, consistent block size, and minimal operator intervention, preparing tires for subsequent shredding or granulation into crumb rubber, and facilitating efficient recycling and material recovery.

| Model | Motor (kw) | Processing range (mm) | Weight (kg) | Dimension (mm) | Production |

| EPS350 | 30.75 | 750-1200 | 1500 | 1100*1200*1490 | 2 |

|---|

Bead wires separator

Specification:

A bead wire separator is a crucial tool in tire recycling machinery for crumb rubber production. It operates on four main principles: mechanical extraction and shearing, force amplification through leverage or hydraulics, rotary motion or pulling mechanism, material clamping and positioning, and automation control in semi-automatic models. These principles ensure the efficient removal of steel wires, allowing the remaining tire material to be processed into crumb rubber and the recovery of steel wires for recycling.

| Model | Motor (kw) | Processing range (mm) | Weight (kg) | Dimension (mm) | Production |

| EPS240 | 15.75 | Tire beads | 1800 | 1520*1180*1200 | 1 |

|---|

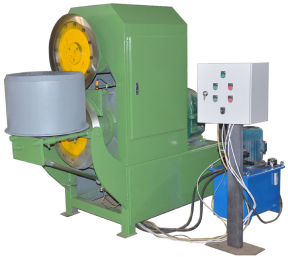

Semi Automatic Crumb Rubber Plant

Specification:

A semi-automatic crumb rubber plant processes raw rubber into smaller granules or crumbs for applications like asphalt modification, rubberized flooring, and molded products. The process begins with raw material preparation, followed by manual sorting and primary size reduction. The shredded rubber is then crushed and ground into finer particles. The system uses sieves or screens to control particle size, and manual adjustments are made to maintain desired output quality. Metal and fiber separation is done using magnetic separators or air classifiers. The crumbs are then dried to ensure stability. The process is then packaged into bags or containers, and manual control and monitoring are essential.

| Model | EPS560P | EPS610/800P | EPS610/1000P |

| Front Roller (mm) | 560 | 510 | 560 |

|---|---|---|---|

| Rear Roller (mm) | 510 | 610 | 610 |

| Roll Length (mm) | 800 | 800 | 1000 |

| Rollers Speed Ratio | 1:1.38 | 1:2 | 1:1.9 |

| Front Roll Linear Speed (m/min) | 22.68 | 23.79 | 24.72 |

| Max Gap (mm) | 16 | 16 | 16 |

| Sliding/Rolling Bearing | Optional | Optional | Rolling bearing |

| Capacity/0.5-5mm (kg/h) | 500-800 | 600-1200 | 1000-2000 |

| Motor Power (kw) | 90 | 132 | 185 |

| Weight (kg) | 17000 | 17500 | 19500 |

| Size R(mm) | 5620×2260×1900 | 5739-2270×1560 | 5899×2270×1560 |

Fine rubber powder grinder

Specification:

A fine rubber powder grinder is a machine used in tire recycling to produce crumb rubber or fine rubber powder. It operates on several principles, including mechanical grinding, friction and impact forces, cryogenic or ambient grinding, force amplification via hydraulics or motors, sieving and size control mechanisms, and automation and precision control in semi-automatic systems. These principles ensure the production of fine rubber powder that meets specifications for use in asphalt, sealants, and various rubber products. The grinder uses blades, discs, or rollers to break down rubber granules into smaller particles.

| Model | EPS450M | EPS550M |

| Roller diameter(mm) | Φ450 | Φ550 |

|---|---|---|

| Roller working length(mm) | 800 | 1000 |

| Bearing type | rolling bearing | rolling bearing |

| Power(kw) | 90 | 105 |

| Weight (kg) | 11000 | 17000 |

| Dimension(mm) | 4520×2110×1450 | 5120×2210×1550 |

| Production(kg/h) | 200-800 | 400-1200 |

Our Certificates

Our Own Recycling Facilities

Organization:

EPS Group

Phone Number:

Email Address:

Website:

www.epstyrerecycling.com

Office Hours:

Monday To Saturday 9:00 AM to 6:00 PM

Office 1

Organization:

Hunan Benji

Environmental Energy Technology Co., LTD

Environmental Energy Technology Co., LTD

Phone Number:

Email

Address:

Address:

Office Hours:

Monday To Saturday 9:00

AM to 6:00 PM

AM to 6:00 PM

Get In Touch

Our team is available to assist with questions, inquiries, and tire range information, as well as advice on vehicle options and services.