Revolutionizing Waste Management with Advanced Batch-Type Pyrolysis Plant

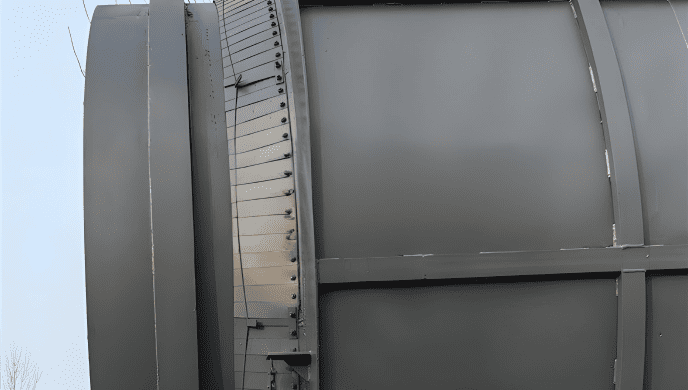

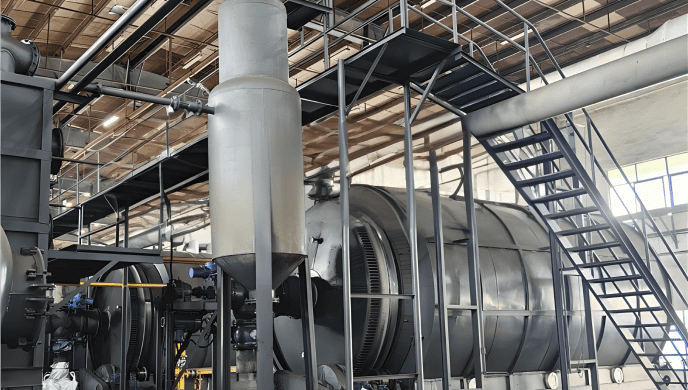

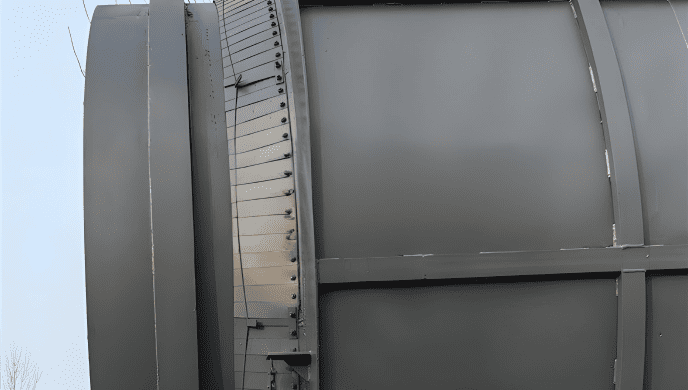

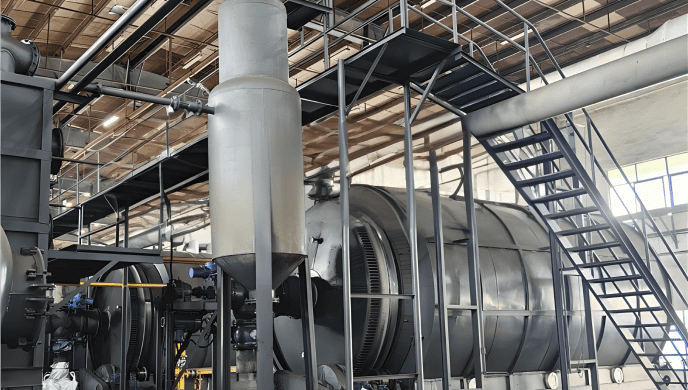

An Advanced Batch-Type Pyrolysis Plant is a specialized system that uses controlled thermal decomposition of waste materials to convert waste into valuable byproducts like fuel oil, syngas(reuse), carbon black, and char.

The Advanced Batch-Type Pyrolysis Plant converts waste materials like plastics, rubber, or biomass into valuable by products through thermal decomposition in an oxygen-deficient environment. The process involves loading materials into the reactor, heating and pyrolysis, condensation and gas separation, collection of solid residues like carbon black or biochar, and flue gas treatment. The reactor is sealed to prevent combustion and the waste is cooled before the next batch. Either a manual or automatic discharge of the solid leftovers occurs. The procedure guarantees environmental compliance while reducing the requirement for external energy.

Revolutionizing Waste Management with Advanced Batch-Type Pyrolysis Plant

An Advanced Batch-Type Pyrolysis Plant is a specialized system that uses controlled thermal decomposition of waste materials to convert waste into valuable byproducts like fuel oil, syngas(reuse), carbon black, and char.

The Advanced Batch-Type Pyrolysis Plant converts waste materials like plastics, rubber, or biomass into valuable by products through thermal decomposition in an oxygen-deficient environment. The process involves loading materials into the reactor, heating and pyrolysis, condensation and gas separation, collection of solid residues like carbon black or biochar, and flue gas treatment. The reactor is sealed to prevent combustion and the waste is cooled before the next batch. Either a manual or automatic discharge of the solid leftovers occurs. The procedure guarantees environmental compliance while reducing the requirement for external energy.

Benefits Of Using Our Advanced Batch Type Pyrolysis Plant

High Energy Efficient

Flexible operation

Eco Friendly

High byproduct value

We supply plants according to the regulation of Government SOP standard of Indian environment standards

Finding The Advanced Batch-Type Pyrolysis Plant For Every Operation Size

The size of an Advanced Batch-Type Pyrolysis Plant depends on various factors such as waste processing capacity, the type of materials being processed, and the scale of operations.

The reactor's capacity determines the minimum plot area needed for a new Advanced Batch Type Pyrolysis Plant (ABAP). For 12-15 ton reactors, a minimum plot area of 3,000 square meters is required, with additional reactors adding 750 square meters.

| Model | EPS-12 | EPS-15 |

| Size of Reactor(M) | D2.8*L7.1 | D2.8*L8.0 |

|---|---|---|

| Daily Capacity | 10-12T/D | 15T/D |

| Power | 36kw/h | 40kw/h |

| Heating Material | Natural gas/Oil/Wood/Coal/LPG/Syngas and so on | |

| Reactor Thickness | 16mm/18mm | |

| Rotate Speed of Reactor | 0.4turn/minute | |

| Cooling Method | Water cycling cooling | |

| Labor Required | 5 - 7 person in two or three shifts | |

Applications Of The Final Product In Different Industries

Pyrolysis Oil

- This substance is utilized as a substitute for renewable fuel oil or furnace oil in boilers, generators, and industrial heating systems.

- This substance can be converted into renewable fuel oil , gasoline, or naphtha.

- The substance is utilized as a fuel for high-temperature kilns.

- Shipping and Transportation

Recovered Carbon Black

- Tire and rubber manufacturing

- Act as a black pigment in plastics and polymers.

- Ink and paint production

- Construction material

- Industrial Fuel Oil

Syngas

- Energy production

- Industrial heating

- Chemical industry

Steel Wires

- Construction Industry

- Manufacturing and Metal Fabrication

- Brush and Broom Production

- Scrap Recycling and Smelting

- Tire-Derived Fuel Support

Our Certificates

Our Own Recycling Facilities

Organization:

EPS Group

Phone Number:

Email Address:

Website:

www.epstyrerecycling.com

Office Hours:

Monday To Saturday 9:00 AM to 6:00 PM

Office 1

Organization:

Hunan Benji

Environmental Energy Technology Co., LTD

Environmental Energy Technology Co., LTD

Phone Number:

Email

Address:

Address:

Office Hours:

Monday To Saturday 9:00

AM to 6:00 PM

AM to 6:00 PM

Get In Touch

Our team is available to assist with questions, inquiries, and tire range information, as well as advice on vehicle options and services.