Introduction to Semi-Continuous Pyrolysis Technology

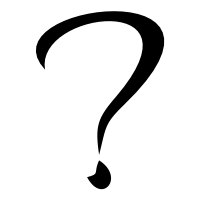

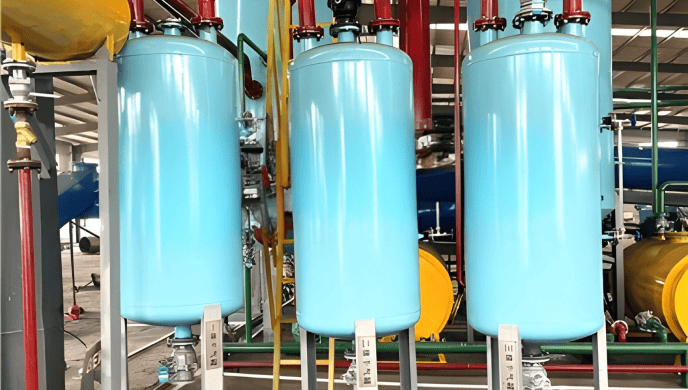

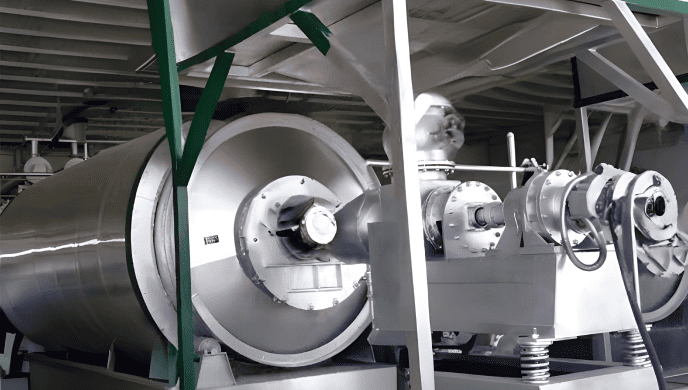

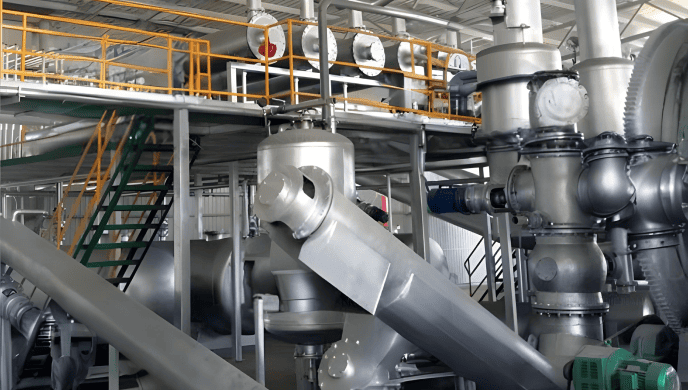

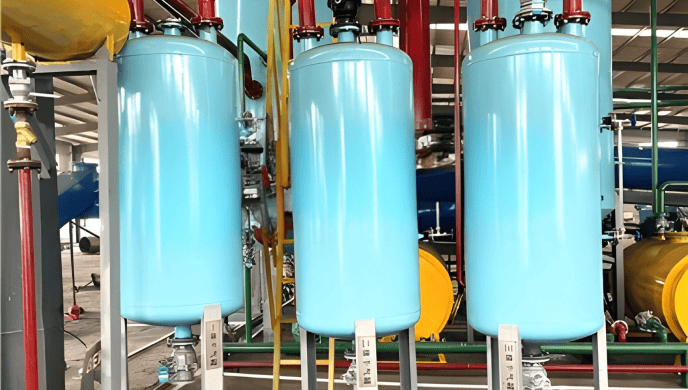

A semi-continuous pyrolysis system that combination of advance batch and continuous operations is called a semi-continuous pyrolysis plant. In comparison to batch systems, it provides a better production flow, and it is less expensive and simpler to operate than fully continuous facilities. It is therefore perfect for medium-sized waste processing facilities. The machine converts waste into alternative fuels and disposes of oil sludge, using an automatic screw feeding, pyrolysis, water cooling discharge, combustible gas recovery, and de-dusting system, under sealed, oxygen-free conditions.

Semi-continuous systems enable ongoing feeding of raw materials and periodic discharging of byproducts, reducing downtime while not operating entirely non-stop. Waste is fed in batches, and the reactor is continuously heated, breaking down waste into fuel oil, carbon black, and non-condensable gases. After pyrolysis, residues are discharged without waiting for the reactor to cool down.

What Is A Fully Continuous Pyrolysis Plant?

A semi-continuous pyrolysis system that combination of advance batch and continuous operations is called a semi-continuous pyrolysis plant. In comparison to batch systems, it provides a better production flow, and it is less expensive and simpler to operate than fully continuous facilities. It is therefore perfect for medium-sized waste processing facilities. The machine converts waste into alternative fuels and disposes of oil sludge, using an automatic screw feeding, pyrolysis, water cooling discharge, combustible gas recovery, and de-dusting system, under sealed, oxygen-free conditions.

Semi-continuous systems enable ongoing feeding of raw materials and periodic discharging of byproducts, reducing downtime while not operating entirely non-stop. Waste is fed in batches, and the reactor is continuously heated, breaking down waste into fuel oil, carbon black, and non-condensable gases. After pyrolysis, residues are discharged without waiting for the reactor to cool down.

Benefits Of Using Our semi Continous Pyrolysis Plant

High Energy Efficient

Maximum Productivity

Lower consumption

Eco protection

Increase Economical Value

Reduced Labour Cost

We supply plants according to the regulation of Government SOP standard of Indian environment standards

Finding the Continous Pyrolysis Plant For Every Operation Size

Selecting the right pyrolysis plant is essential for effective waste management and maximizing profitability. Key considerations include the plant's size, model, and specific operational needs to ensure optimal performance. When choosing a pyrolysis plant, assess the type and volume of waste you'll process, the required daily capacity, and whether a batch, semi-continuous, or fully continuous system suits your operation. It is focused on energy efficiency, environmental compliance, automation levels, labor requirements, and budget constraints. For smaller or experimental projects, a small-scale plant may be ideal.

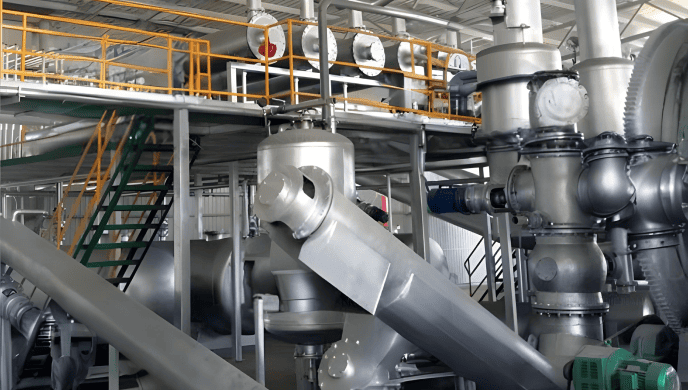

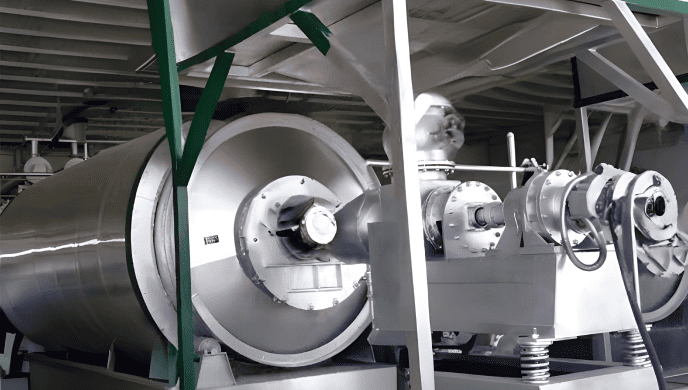

EPS offers 3 different types of semi-continuous pyrolysis plants which is capacity of 10-12 MT/DAY, 12-15 MT/DAY is suitable for middle-scale operations., and 15-20 MT/DAY; you can choose a plant according to your requirements and budget.

| Model | EPS-12 | EPS-15 | EPS-20 |

| Size of Reactor(M) | D2.8*L7.1 | D2.8*L8.0 | D2.8*L8.8 |

|---|---|---|---|

| Daily Capacity | 10-12T/D | 15T/D | 16-20T/D |

| Power | 36kw/h | 40kw/h | 56kw/h |

| Heating Material | Natural gas/Oil/Wood/Coal/LPG/Syngas and so on | ||

| Reactor Thickness | 16mm/18mm/20mm | ||

| Rotate Speed of Reactor | 0.4turn/minute | ||

| Cooling Method | Water cycling cooling | ||

| Labor Required | 4-6 person in two or three shifts | ||

Applications Of The Final Product In Different Industries

Pyrolysis Oil

- Sold directly.

- fuel for the combustion chamber's heating

- fuel for many industries such as cement, power, iron, brick, and boilers;

Recovered Carbon Black

- Sold directly.

- Use carbon black grinding equipment to convert carbon black into higher-quality carbon black.

- recycled and turned into fuel

Syngas(reuse)

- Alternative fuel to heat the main pyrolysis furnace after being processed by condenser and manifold.

- Collect separately for other use.

Steel wires

- Recycling in Steel Industry

- Construction Industry

- Bricks or Road Material Reinforcement

Our Certificates

Our Own Recycling Facilities

Organization:

EPS Group

Phone Number:

Email Address:

Website:

www.epstyrerecycling.com

Office Hours:

Monday To Saturday 9:00 AM to 6:00 PM

Office 1

Organization:

Hunan Benji

Environmental Energy Technology Co., LTD

Environmental Energy Technology Co., LTD

Phone Number:

Email

Address:

Address:

Office Hours:

Monday To Saturday 9:00

AM to 6:00 PM

AM to 6:00 PM

Get In Touch

Our team is available to assist with questions, inquiries, and tire range information, as well as advice on vehicle options and services.